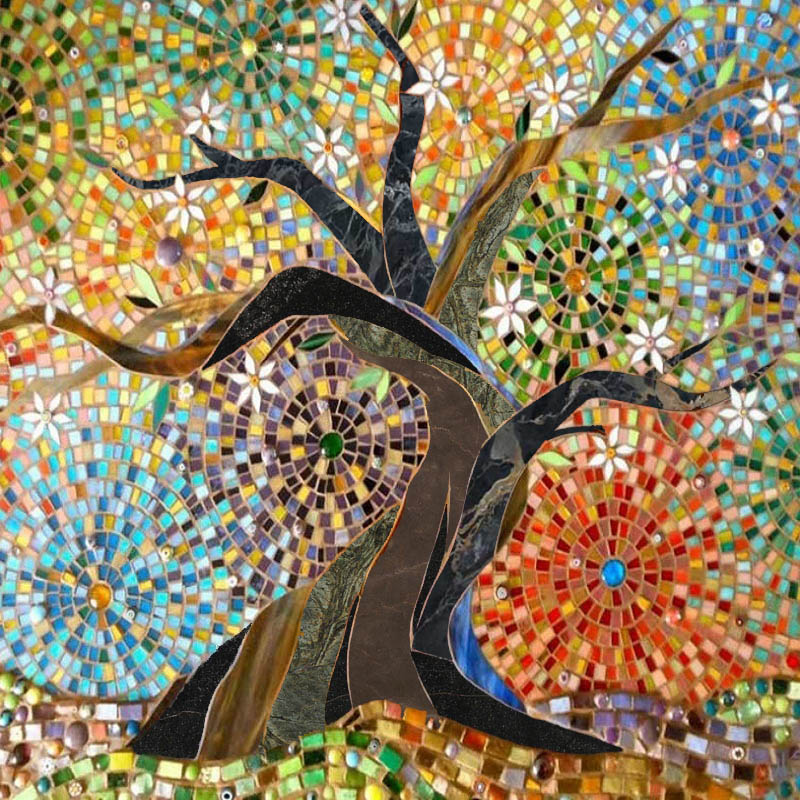

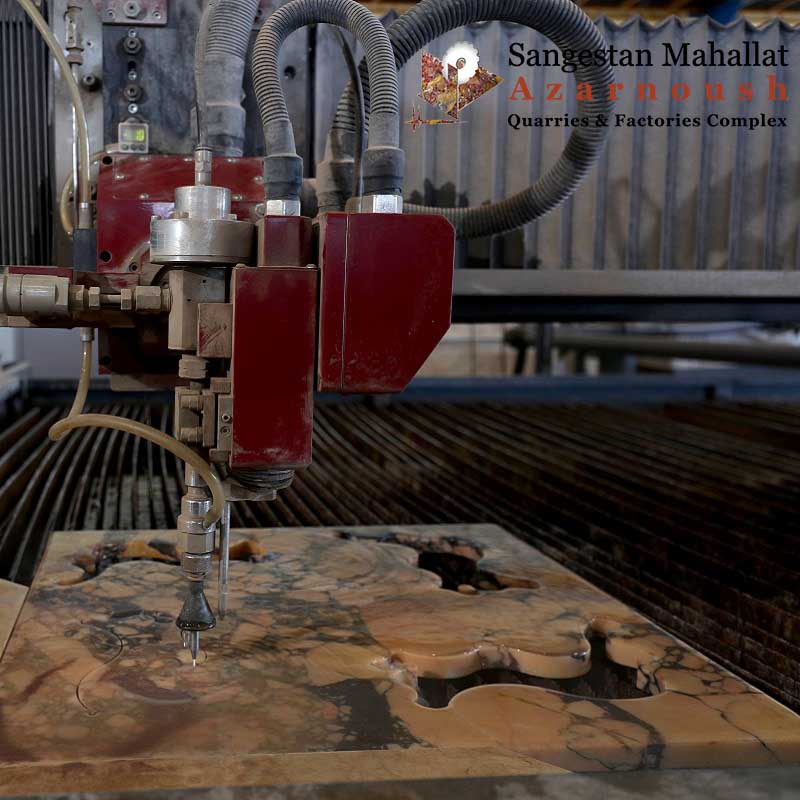

1300 - Making various shapes with "Waterjet"

"Waterjet" device of Sangestan company is one of the best, most modern and most equipped "waterjet" devices available in Iran. Using this device, we can execute all classic and modern designs with the best quality and have any kind of two-dimensional shape with the best and highest quality in the exterior or interior of our house.

- 100

- 20

"Waterjet" device of Sangestan company is one of the best, most modern and most equipped "waterjet" devices available in Iran. Using this device, we can execute all classic and modern designs with the best quality and have any kind of two-dimensional shape with the best and highest quality in the exterior or interior of our house.

"Waterjet" refers to cutting technology using high pressure water flow. In 1950, Norman Franz, a natural resources and forestry engineer, built a machine to cut and shape giant timbers that made it easier to cut lumber using high-pressure water flow.

In 1970, another inventor added a new waterjet by adding abrasives to the water flow. From that date until today, the world industry has been able to have the best cutting machines by relying on the science and knowledge of modern "waterjet".

Waterjets can easily cut the hardest objects and the most complex angles. In other cutting methods, the material may burn, melt or crack, but the "waterjet" is inherently cold-cut and does not generate heat. "Waterjet" machines are much cheaper than laser cutting machines. This, along with other Waterjet capabilities, has made it more popular with manufacturers than Waterjet.

"Waterjet" does not produce dust during operation and cutting, so it does not have the hazards of fiber machines and asbestos, and is basically an environmentally friendly industry.